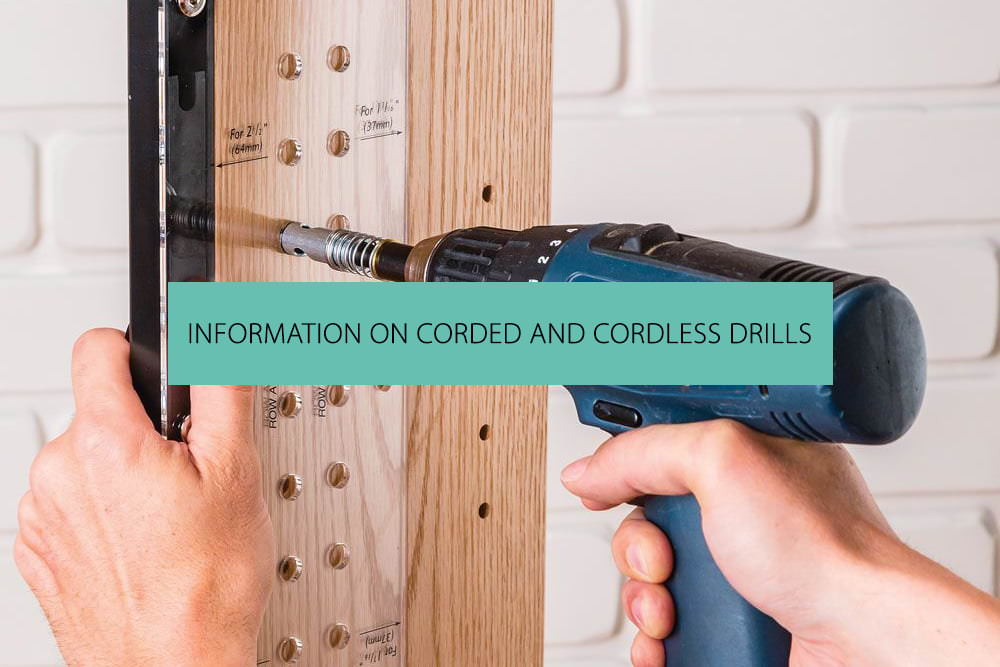

The main advantage of cordless drills is its mobility.

Drills are one of the most commonly used power tools. There are many types of drills available in the market, some of which are suitable only for particular drill bits. The latest innovation in the drills are Cordless Drills.

The main advantage of cordless drills is their mobility. Cordless drills must be charged regularly and can work for an hour or two, depending on the full charge time. Most DIYers prefer carrying an extra battery so they don’t have to wait and charge it to continue their work. Charge time and weight are the only issues with the least expensive models. Corded power drills are a powerful tool to drill holes when it comes to ability and function.

Other types of drills available in the market are corded electric drills. A corded electric drill requires cord plugs and a powerpoint to carry on work. Electric drills have powerful motors built into them and are measured in watts. Most of the drills available in the market are also available with variable speed dial controllers, which means you can control the speed of the drill in case you want to drill a hole at a slow speed. Makita Cordless Drills are a known manufacturer and manufactures stunning cordless drills. Makita Drills have got a unique design and shape, and that’s what makes them different from other drills.

They feature a slimmer body and are slightly angled, which makes them comfortable for use. Other Cordless drills available in the market are comparatively heavier than Makita Drills.

Drill – The never wandering friction that builds homes

Technology, engineering and innovation have evolved and excelled through the ages, and so has the technology of Drill Bits, getting beyond the primitive and bequeathing the utmost advantage to mankind.

May it be drilling a rock, wood, metal, diamond, or so on, the fundamentals have been unique, yet the purpose, application and types of drilling and drill bits have varied time and time again. They have changed the phase with their innate ability to cut and make holes in order to make one element fit into another or create chasms and crevices. Boundless are their functions and application that are exceedingly crucial in joining, building or attaching parts.

Though their basic function is to cut cylindrical holes, it’s proven far too sublime in fitting and fixing things together. The drill bits are the attachments held in the drill, which provide the bits with momentum and propel them with high-power torque, creating force to penetrate the hardest surface possible. Enmeshing the technology of functionalities of two diverse components, i.e. the drill and drill bits, fastening materials have been immeasurably easy than it may have been imagined.

It is supposed that the very beginning of the drill was some thirty-five thousand years ago, wherein the drills had something more than a pointed rock that was spun between the hands. Later came the ‘bow drill’, a prominent development that holds the chronology of the ancient Harappans & Egyptian ages. In 1889, Arthur James Arnot and William Blanch Brain invented the first electric drill in Melbourne. Later, in 1895, in Stuttgart, Germany, the revolutionary portable drill was developed by Wilhelm Fein.

From manually operated to electric drills, the entire range includes several models, viz. Bow Drill, Breast Drill or the egg beater drill, Brace and Bit, Push Drill – a tool that uses a ‘ratchet’ mechanism, Pin chuck, Pistol Grip (Cordless) Drill, Rotary Hammer Drill, Cordless Drills, Drill Press, Geared head Drill Press, Radial Arm Drill Press, and Mill Drill, to name a few.

Basic Safety Tips For Using Drills

Whether using a corded or cordless drill there are some basic precautions that one should keep in mind:

- Use protective gear such as safety glasses, gloves, and dust masks for intensive jobs involving lots of dust or debris.

- Earmuffs can help with the noise over extended periods of drilling.

- Keep loose-fitting clothing and jewellery away from the moving parts of drills.

- Keep a firm and steady hand while drilling. If necessary, make sure what you are drilling is also steadied by some means, such as a clamp or vice.

- Always ensure that the drill bit is locked tightly in the chuck jaws.

When using cordless drills:

- Keep your batteries well-charged. Preferably, have at least two batteries available for big jobs, so you can keep drilling while the other charges.

When using corded drills:

- Always makes sure you are aware of the power chord. Don’t let it get wrapped around your leg, or anywhere on your body, as you work.

- Don’t be impatient and tug on the electric cord if it doesn’t reach. Rather use extension cords to further your reach with cordless drills.

There are varied features of a Drill Bit

The point angle

It’s the formation of the angle at the tip of the bit, which is determined by the type of material in which the bit will be functioning or operating. A larger point angle is required to operate on harder surfaces or materials, and a sharper angle is needed to work on softer materials. Wear rate, Hole Shape, Wandering, Chatter and other features are controlled by the exact point angle for the hardness of the material.

The Spiral

This point in the bit controls the rate of chip removal. Mostly, in high feed rate applications under low spindle speeds, a fast spiral drill bit is used, where the removal of a large volume of swarf is needed. Also, for cutting applications where high cutting speeds are conventionally used, low spiral drill bits are commonly used, and when there’s a tendency of the material to vex on the bit or, in some cases, choke the hole, like aluminium or copper.

The mechanic

They are extensively used, and the term ‘mechanic’ has been given by vendors to describe the length of the bit.

The Jobber

Similar to the Mechanic type of drill bits, the Jobber is an extensively used term by vendors in order to describe the length of the bit.

Materials used for Coating

Black oxide – An expensive black coating; it provides lubricity and is corrosion & heat-resistant. It has a longer life than conventional high-speed steel bits that are uncoated.

Titanium nitride – Titanium Nitride (TiN) can extend the cutting life thrice or four times when used to coat a high-speed steel bit; it is known to be an extremely hard ceramic.

Titanium Aluminium Nitride (TiAIN) - Yet another coating used quite frequently; it has five or more times extended tool life.

Diamond powder – Is often used as an abrasive; also used for cutting stone, tile, and other awfully hard materials. They have to be constantly cooled by water to prevent damage to the bit, or the piece it’s used on, for heat is generated in large amounts during usage.

Zirconium nitride – For a number of craftsman tools, it’s been used as a drill bit coating.

Steel

Soft low Carbon Steel –These are only used in wood, for they cannot hold an edge properly and must be sharpened frequently.

Cobalt Steel Alloys – These bits vary significantly on high-speed steel that comprises more Cobalt. They hold their hardness at much higher temperatures, thus, they quite conveniently drill stainless steel and various hard materials, which is a unique benefit.

High-Speed Steel (HSS) - As a form of tool steel, they are more resistant to heat. More often used to drill metals, hardwood and various other materials. Their cutting speed is higher than carbon steel bits. They substitute for carbon steels.

There are other types of Drill Bits viz. Polycrystalline diamond (PCD) and Tungsten carbide.

Every bit has diverse applications for various surfaces and objects:

- Universal Bits - The range comprises of: The Twist Drill Bits, Step Drill Bits, Unibit and Hole Saw. The Twist Drill Bit was invented by Steven A Morse of East Bridgewater, Massachusetts, in 1861.

- Metal Drill Bits - Metal Drill Bits constitute yet another vast range, viz. Centre & Spot Drilling Bits - these are used to make holes in Lathe Centres and Spotting Hole Centres. Then you have the Ejector Drill Bit, Core Drill Bit, Counter Sink Bit, Indexable Drill Bit, Gun Drill Bit, Straight fluted Bit, Left-hand Bit, Metal Spade Bit & Trepan.

- Wood Drill Bits - The Wood Drill Bit includes Wood Spade Bits, Lip & Spur Drill Bits, Forstner Bits, Spoon Bits, Auger Bits, Centre Bits, Hinge Sinker Bits, Gimlet Bits & Adjustable Wood Bits.

- Drill Bit Shank - Diverse combinations of different types of Shank or Chuck offer varied performances. The advantage is that it enables the high-end torque with tremendous centring accuracy.

- Other Materials - This category consists of another vast range of Masonry Drill Bits, Diamond Core Bits, Glass Door Bits, Installer Bits, and PCB through Hole Drill Bits.